Client

Power Grid Equipment Manufacturer

Application

Transformer Substation Type Testing

Date

2014

Introduction

A heat run test, as outlined in IEC 62271-202, is essential for assessing the thermal performance and safety of transformers, transformer substations, and low-voltage switchgear under operational loads. This test verifies that the equipment can handle expected thermal stresses without overheating, ensuring reliability and compliance with international standards. By simulating real operational conditions, the heat run test evaluates whether the components can maintain stable temperatures within prescribed limits, thereby preventing insulation failures, component degradation, or unsafe conditions during regular use. Conducting this test according to IEC 62271-202 is crucial for validating the long-term durability and operational safety of electrical distribution systems.

Challenges

Heat run testing presents several challenges, including the need for precise voltage and current control, accurate data acquisition, and stringent safety measures. High-accuracy power supplies are essential to accurately replicate operational conditions , while multi-channel data acquisition systems must capture temperature, voltage, current, and power in real-time. Managing the volume of data during the long test duration and ensuring compliance with EN 50191 safety standards is a another challenge. High test currents – up to 6300A – are required for low-voltage switchgear.

OUR SOLUTION

Medium Voltage Transformer

Substation Test System

Substation Test System

Our solution includes two 3-phase AC power supplies, two precision power analyzers, and a 120-channel temperature data acquisition unit, all fully remote-controlled via Ethernet from the control room.

The primary power supply provides up to 500 kVA with 6 selectable voltage ranges up to 3000V, meeting the short-circuit voltage requirements for medium-voltage transformers up to 36 kV and 5 MVA.

The secondary power supply is specifically designed for high-current testing of low-voltage switchgear up to 6300 A.

Custom data logging software records all electrical and temperature data with time stamps throughout the heat run, allowing individual channel configurations and limits to safeguard the entire test process. For maximum operator safety, the test field operation is protected by a configurable safety controller and safety components in compliance with EN 50191.

Highlights

Medium Voltage Transformer, Switchgear and Substation Test System

Features

Medium Voltage Transformer, Switchgear and Substation Test System

3-Phase AC Power Supply 500kVA

Provides up to 3000V and 500kVA for high power requirements during heat-run tests.

3-Phase High Current Supply 6300A

Delivers up to 6300A for high current switchboard testing.

Precision Power Analyzers

Ensure precise power measurements during testing.

120-Channel Temperature Acquisition

For precise and simultaneous temperature measurements at all points for the test setup.

Data Logging with Limit Monitoring

Custom Software collects all data and monitors critical limits in real-time.

Full Remote Operation

Allows complete remote control of the system from the control room via Ethernet.

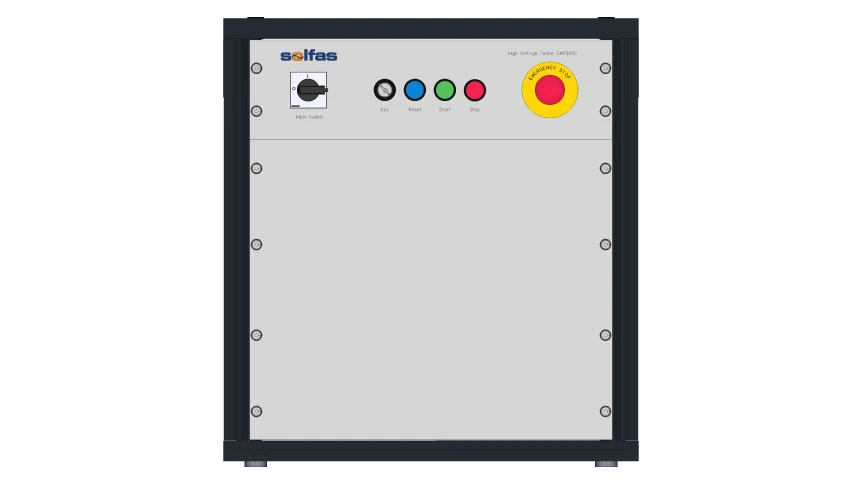

Safety equipment according to EN50191

Ensures operator safety in compliance with safety standards.

Power Supply Limits Switch Off

Automatically shuts down to protect equipment and personnel when given limits are ecxeeded.

Technical Specifications

| Power Supply 1 | Sine Inverter Power Supply 3 phase AC 500kVA 50-60Hz 0… 500/750/1000/1500/2250/3000V |

| Power Supply 2 | Sine Inverter Power Supply 3 phase AC, 100kVA, 50-60Hz 0…6300A |

| Power Measurement | Precision Power Analyzer Basic accuracy 0.03% Current Sensors 100A, 1000A and 10kA Voltage Sensor 3AC 8,4kVrms |

| Temperature Measurement | Precision Data Aquisition Unit 120 Channels J-Type thermocouple |